Why Galvanized Earthing Strips Are Critical for Substation Safety

Electrical substations are an integral part of the power distribution system. They manage high currents (up to hundreds of thousands of Amps) and high voltages, which contain hazardous electrical energy. There are many safety precautions that must be incorporated. Galvanized earthing strips for substation safety are among the most important. Earthing strips are conductive metal strips that serve as an electrical safe path to ground fault currents, resulting in dangerous voltage that can lead to equipment failure, fires, or serious electrical hazards to life.

Importance of Galvanized Earthing Strips in Electrical Systems

Galvanized earthing strips are crucial components for ensuring the integrity of any electrical system. Rather than utilizing standard earthing metal strips, galvanized earthing strips are coated in zinc, which significantly improves their applications in extreme environments. Galvanized earthing strips do more than just offer basic earthing functionality; they provide reliable electrical outcomes and are specifically designed to overcome corrosion that may compromise the system’s safety during operation over many years.

In electrical infrastructure, these straps create a low-resistance path that allows fault currents to be safely returned to ground potential. This eliminates any dangerous voltage differences between circuit components of electrical equipment and lowers the potential for electrical shock hazards for maintenance workers. The galvanizing process gives the straps their electrical characteristics, which are not affected by moisture, common chemicals, or the often high and low temperatures inside of substations.

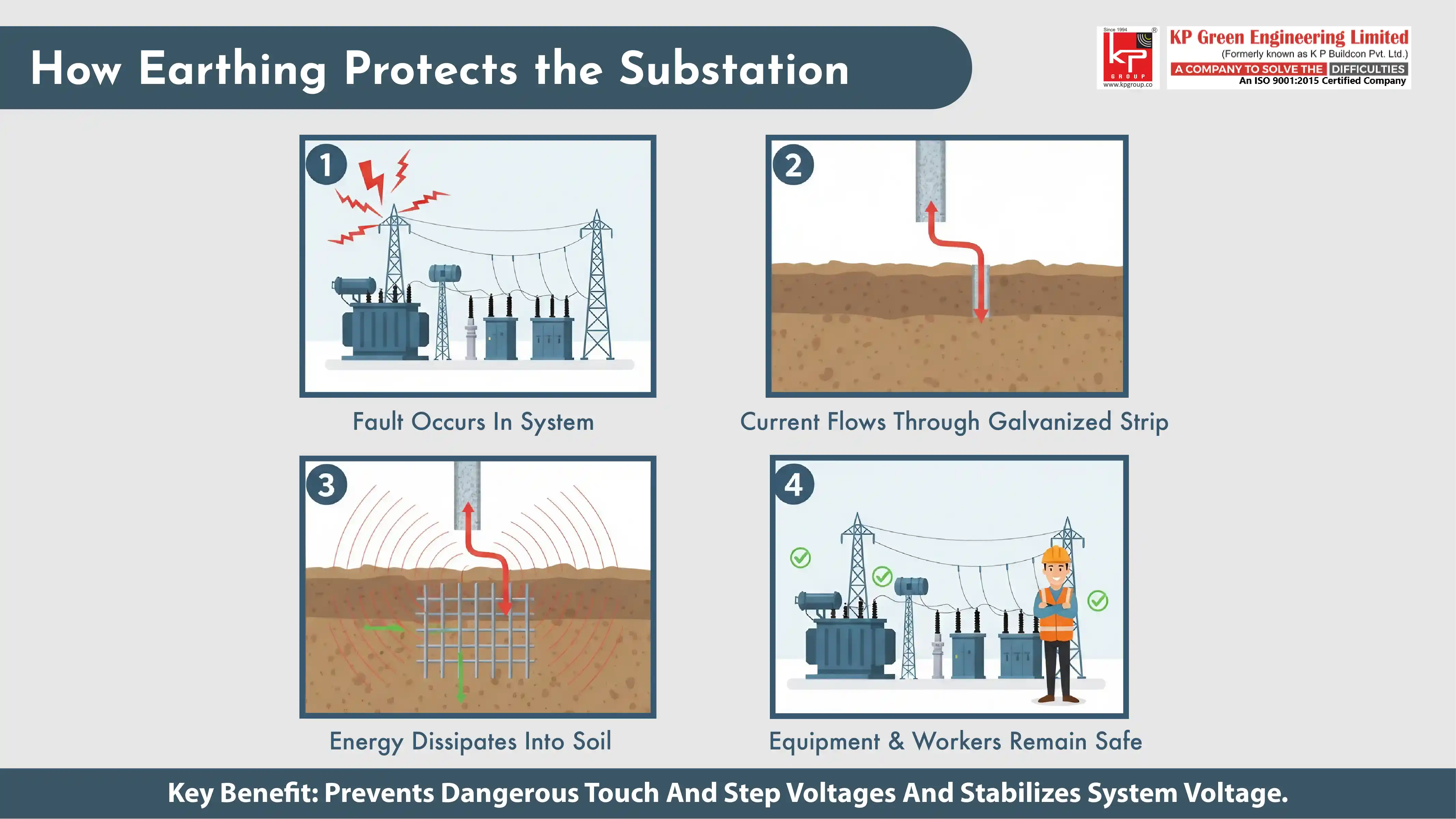

Role of Earthing in Substation Safety

Earthing safety in substations is based on having multiple paths that are interconnected to sustain fault currents. Electrical faults create very high current levels that must be diverted without delay to avoid equipment damage and worker injury.

Earthing systems must be installed properly and utilize galvanized strips to provide a network that disperses equivalent fault currents safely into the ground while preventing dangerous voltage gradients that could potentially injure or kill individuals within the safe working distance limits specified by jurisdictional regulations.

The earthing system also provides system voltage stability during the normal operation of the system, acting as a reference for electrical measurements and control systems. Stability is essential for the protection of sensitive electronic equipment and the uniformity of power quality supplied to end users.

Benefits of Using Galvanized Earthing Strips for Substations

Corrosion Resistance and Long-Term Reliability

The main benefit of galvanized earthing strips is their excellent resistance to corrosion. The zinc coating serves as a sacrificial layer to inhibit oxidation and degradation of the underlying steel or iron. Which leads to reliable electrical connectivity for 25-30 years or more, reducing downtime and maintenance costs significantly.

The strip's common cross-sectional area and similar material properties help provide confidence for engineers when predicting the performance of electrical properties in safety systems. This predictability is particularly important in determining ground resistance values and ensuring the established safety levels are achieved.

Enhanced Electrical Grounding for Safety

Electrical grounding and substation safety require to be low-resistance connections, ensuring stability over time. Galvanized earthing strips offer better electrical conductivity than a number of other materials, allowing fault current to flow without undue voltage buildup.

The earthing strips are constructed with a uniform cross-sectional area and consistent material properties, allowing for predictable electrical performance on which an engineer could rely during safety system design. Predictable electrical performance is important for calculating ground resistance values and ensuring system performance meets electrical safety requirements.

Cost-Effectiveness Compared to Other Earthing Materials

While copper earthing materials have excellent conductivity, their cost and risk of theft make them less suitable in many situations within a substation environment.

Galvanized steel strips are a more cost-effective option, delivering the same level of performance, as the process of galvanization extends the service life of steel strips and typically reduces overall lifecycle costs through less frequent replacement and maintenance costs.

While aluminum strips do provide another option, they suffer corrosion issues and do not provide the reliability of joint connections that galvanized steel strips offer. The cost of selecting galvanized strips can be significant when applied in a well-developed substation installation.

Electrical Grounding and Substation Safety Explained

How Earthing Prevents Electrical Hazards

Proper earthing systems using galvanized strips create multiple safety layers that protect both equipment and personnel. When electrical faults occur, the earthing network provides a low-impedance path that quickly conducts fault currents away from equipment frames and structures. This rapid current dissipation prevents dangerous touch and step potentials that could injure maintenance workers.

The earthing system also provides overvoltage protection during lightning strikes and switching surges. By creating a direct path to ground, the system prevents voltage buildup that could damage expensive substation equipment or create fire hazards

Connection Between Fault Current Dissipation and Safety

The release of fault current through galvanized earthing strips occurs in accordance with known electrical laws, which allows engineers to design safe operating environments. The resistant nature of the strips allows the maximum amount of current to flow during fault conditions, which facilitates the rapid operation of protective devices such as circuit breakers and fuses in order to de-energize the fault.

It is important to note that the fault current must have a path to ground in order to keep it safe from traveling through the unintended path of a person, through their body. Without earthing, fault current could energize equipment frames, energizing the frame and creating a risk of electrocution. The earthing network allows for fault current to travel through a preferential route on the current flow path into the ground.

Real-World Examples of Earthing in Substations

Modern substations employ extensive earthing networks that interconnect all equipment through galvanized strips buried beneath the facility. These networks typically include equipment grounding conductors, static wire grounds, and structure grounding systems all connected through a common earthing grid.

Power transformers, switchgear, and control buildings all connect to this grid through galvanized earthing strips that provide reliable fault current paths. The strips also connect to ground rods and other grounding electrodes that extend the earthing system deep into the surrounding soil.

Earthing Strip Installation Best Practices

Site Preparation and Material Selection

Proper earthing strip installation best practices begin with a thorough site analysis to determine soil resistivity and environmental conditions. Site preparation includes excavation planning, soil treatment if necessary, and coordination with other underground utilities. Material selection must consider expected fault current levels, environmental exposure, and local safety standards.

Galvanized strips should be sized according to fault current calculations and selected with appropriate zinc coating thickness for the expected service environment. Strip dimensions must provide adequate current-carrying capacity while maintaining mechanical strength for installation and long-term service.

Proper Installation Techniques for Maximum Safety

Installation errors can severely impact earthing system functionality and create safety hazards in many types of operations over time. Errors associated with installation can also compromise the earthing components placed in service. Common errors include unprepared joints, mixing dissimilar metals, creating galvanic corrosion, insufficient burial depth, and exposing strips to mechanical damage.

Not providing proper connection tightening torque can create a high-resistance joint at the connection, compromising fault current flow or hot spots during operation. Using non-galvanized hardware in a galvanic application can create corrosion cells and eventually failure of the connection.

Common Mistakes to Avoid During Earthing Installation

The performance and lifespan of earthing systems are greatly influenced by installation methods. Galvanized strips require strong mechanical and electrical connections at all junctions, which are usually secured by bolted connections that have appropriate fittings. All junctions should be protected from corrosion with joint compounds and, where necessary, should be housed in weatherproof enclosures.

Burial depth should comply with local standards of burial depth while providing protection from mechanical damage and environmental influences. Good backfill materials should provide good soil contact and protect against corrosive exposure that will compromise the galvanized coating.

Safety Standards for Substation Grounding

IS and IEC Standards for Earthing Systems

International organizations such as the International Electrotechnical Commission (IEC) and national organizations such as the Bureau of Indian Standards (IS) define safety standards for substation grounding. These standards delineate the minimum standards required for the design, installation, and testing of earthing systems. These minimum standards determine and ensure adequate safety margins for the protection of personnel and equipment.

The guidelines provided in IS 3043 and IEC 61936 cover all aspects of substation earthing design, including traveler sizing, connection types, and system testing. Usually, utilities must comply with these standards during their installations. These standards are also recommended for industrial installations.

Compliance Requirements for Utilities and Developers

Utilities and project developers will need to validate that they are following applicable earthing Standards using detailed engineering calculations and complete testing programs. Documentation includes performing soil resistivity measurements, calculating fault current and verifying testing that would show installed systems comply with the design standards.

Regulatory authorities may conduct an ongoing compliance audit to confirm that earthing systems remain safe and reliable. Such audits usually involve visual inspections, electrical testing, and examination of maintenance records to confirm that safety standards continue to be met.

Routine Testing and Maintenance for Safety Assurance

To maintain the effectiveness of earthing systems over time, they will need to be tested and maintained regularly. The ground resistance test should be conducted at least once a year, or after any substantial modification to the earthing system, to confirm low resistance has remained. Visual inspections of the earthing system can identify corrosion, mechanical damage, or loose connections that could present a safety hazard.

Thermal imaging surveys can show high-resistance joints that may not show a visual inspection. Preventive maintenance, such as connection re-torquing at scheduled intervals, joint cleaning, and replacement of degraded components before they create safety issues, should be components of an organization’s preventive maintenance program.

Are you looking to buy galvanized earthing strips for your project’s substation's safety?

Contact Us NowConclusion

Galvanized earthing strips for substation safety constitute a key investment for the protection of the electrical system and offer reliable service for decades. The factors of corrosion resistance, electrical characteristics, and cost effectiveness make galvanized earthing strips the most common choice for all station earthing applications. Following proper selection, installation, and maintenance of these systems will keep the personnel and the equipment protected while maintaining a high level of safety for any station. As electrical infrastructure continues to change, galvanized earthing strips will remain a best practice for safely and reliably keeping electricity moving for the communities and industries that use it daily.

Frequently Asked Questions:

About Us

KP Green Engineering Ltd. provides complete engineering and steel structure manufacturing solutions worldwide, serving industries such as renewable energy, telecommunications and beyond.

Get In Touch

Latest News

KP Green Engineering Scales Durable, Low-Carbon Infrastructure

KP Green Engineering bags landmark order worth Rs 819 crore from BSNL for 4G telecom infrastructure

Gujarat Deputy CM Harsh Sanghavi Inaugurates KP Green Engineering's Matar Facility