Pre-Engineered Buildings for Renewable Energy Sites: Benefits & Use Cases

The renewable energy industry in India is growing rapidly and dynamically, with targeted 2030 non-fossil fuel capacity goals. Animals are reforging by the day across India with solar parks, wind farms and hybrid energy solutions. The infrastructure needs to be ready for the expansion regarding both scale and urgency. It's here that pre-engineered buildings for the renewable energy sites are the backbone of this construction. The method of building pre-engineered structures solutions lends itself naturally to the speed of construction, sustainability and to moderate construction budgets for modern energy project structure constructions.

As opposed to conventional construction methods that create the structures at the site of construction, renewable energy site construction using pre-engineered buildings rely on components that are manufactured in a factory, prefabricated to eventually send to the job site and be assembled rapidly on site. The method of using pre-engineered buildings has reshaped the way control rooms, equipment storage structures, maintenance shops, and operations centers are constructed at solar and wind installations across the country.

What Are Pre-Engineered Buildings for Renewable Energy Sites?

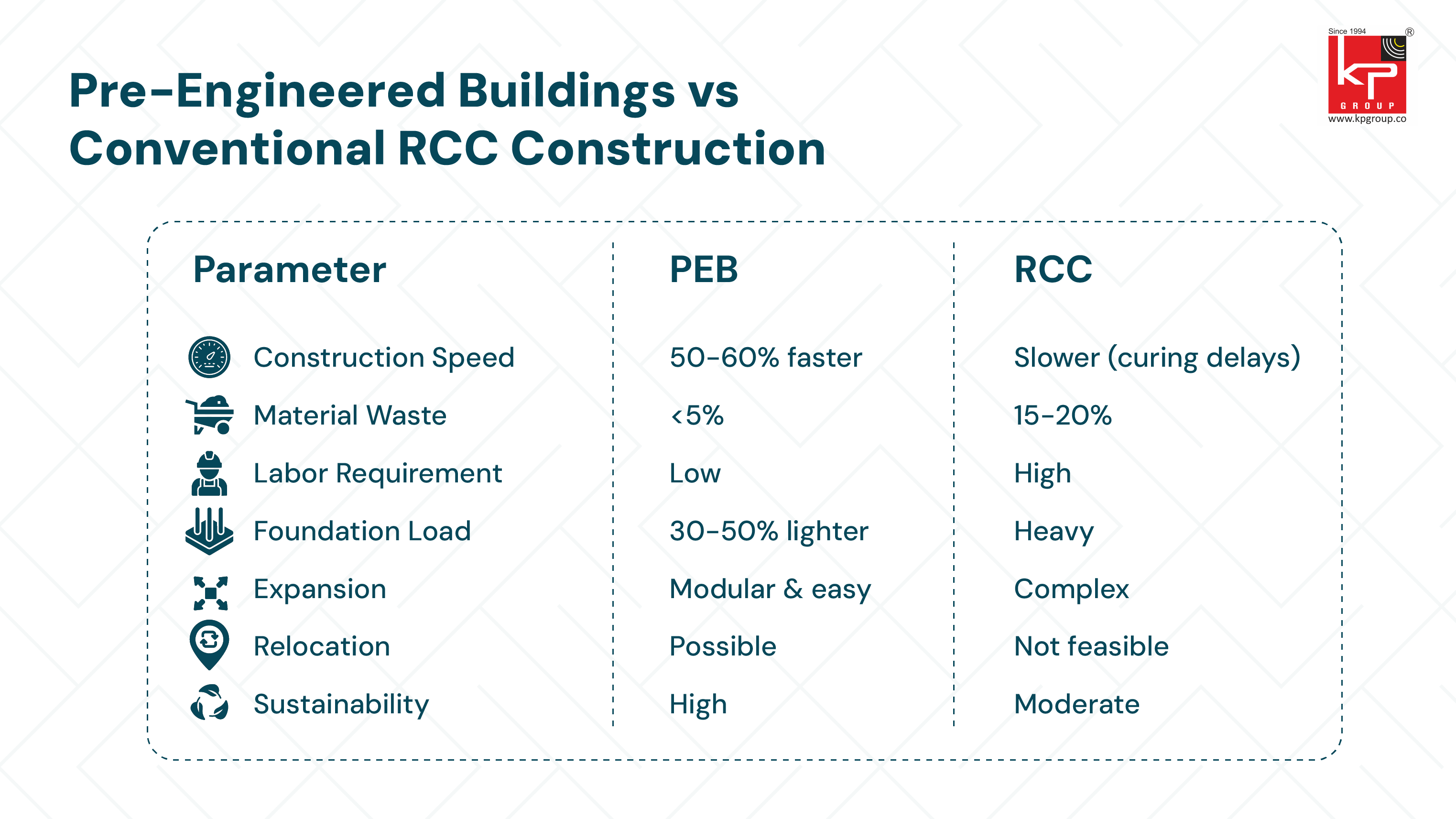

Pre-engineered buildings (PEBs) are steel composites where the whole structure is designed, manufactured, and pre-cut in the factory, and then delivered to site for assembly. The prefabrication concept markedly departs from conventional construction, where everything is frequently measured, cut, and assembled on-site with generous margins for error and delay.

Pre-engineering metal buildings for solar farms and wind developments are quite different than conventional RCC (Reinforced Cement Concrete) constructions in their construction timeline, material efficiency, and adaptability.

Why Pre-Engineered Buildings Are Ideal for Renewable Energy Infrastructure

Cost Savings of Pre-Engineered Buildings for Energy Projects

The primary motivation behind nearly all decisions related to infrastructure in the renewable energy sphere is economic efficiency. Projects are designed with very slim margins of profitability and developers endure great competition in the auction process. Cost savings with Pre-Engineered Buildings (PEB) for energy projects generate benefits in multiple ways:

- Less Material Waste: With factory fabrication, the material waste associated with on-site construction is removed, saving up to 30-35% overall. Every steel member is cut to the exact length with minimal remnants of scrap metal, which are then recycled while under the same roof.

- Less Labor Cost: Erecting PEBs uses fewer specialized workers and the duration is less, which yields labor savings of 20-40% when compared to conventional construction. Delivery and assembly of the PEBs take 4 to 6 weeks. Traditional construction takes around 25 weeks.

- Less Foundation Cost: Steel structures typically weigh 5–15% less than the equivalent reinforced concrete buildings. The lighter structures yield an easy to construct and use smaller, less costly foundations, which can be important in unsafe soil conditions that arise on the sites of many remote renewable energy projects.

- Lifecycle Costs: Initial costs may be comparable to comparable construction, but PEBs add cost advantages through less maintenance requirements, ease of expansion and relocating when site conditions change.

Time-Efficient Building Solutions for Renewable Energy Plants

The speed to completion is vital in renewable energy projects because if it is not completed on time, revenue from power purchase agreements may be lost, and there may be penalties. There are time-efficient building solutions for renewable energy plants using pre-engineered building (PEB) technology, which squeezes the construction schedule to the smallest timeframe possible because:

- Concurrent Activities: As the foundation work is proceeding on-site, fabrication of the building components is also underway in the factory, providing parallel processing which may save more than half the time off project schedule.

- Weather-Independent Fabrication: Even during monsoon seasons or extreme heat, the factory can undertake production unhindered by weather delays that conventional construction would experience.

- Standardized Assembly: In contrast to concrete buildings requiring curing time, PEB technology allows rapid assembly using bolted connections, building tall structures over short timeframes without a lot of common mistakes.

- Scalability: While the solar park expands from Phase I to Phase II, or the wind farm adds turbine clusters, PEB structures are very easy to replicate, utilizing previously established designs and established supply chains.

Key Benefits of Pre-Engineered Buildings for Renewable Energy Sites

The pre-engineered building (PEB) benefits for renewable energy sites extend far beyond cost and time efficiencies:

- Structural Efficiency and Design Flexibility: Clear-span designs up to 100–120 meters wide can facilitate large-scale inverters, transformers and battery storage systems with no obstructions on the interior. Expansion joints along with a modular design allow buildings to expand or grow with project increases in capacity.

- Durability in Extreme Weather: Renewable energy sites often occupy extreme climates-summer temperatures above 50 C in desert cases, coastal sites with salt-laden air, or wind farms at high altitudes with blizzards and sub-zero winters. PEB designs utilize galvanized steel and protective coatings, resisting corrosion, UV degradation and thermal expansion much better than conventional building materials.

- Ease of relocation and Expansion: Pre-engineered buildings can be disassembled, relocated and reassembled whereas permanent structures from RCC can not typically be either relocated or reassembled. This becomes a beneficial flexibility as renewable energy developers continue to negotiate land lease agreements with landowners and government agencies, as site conditions could change at any point.

- Compatibility with Renewable Assets: Today's designs for pre-engineered buildings actively factor in mounting for solar panels on rooftops, cable trays for power evacuations systems and HVAC for temperature-controlled rooms housing hardware and control systems. In addition, the structural steel shear frame can explore accommodating overhead cranes for turbine components in wind farm workshops.

The sustainability advantages of pre-engineered metal buildings align perfectly with the environmental ethos of renewable energy projects, creating a synergistic relationship between building methodology and project purpose.

PEB Applications in Solar and Wind Energy Projects

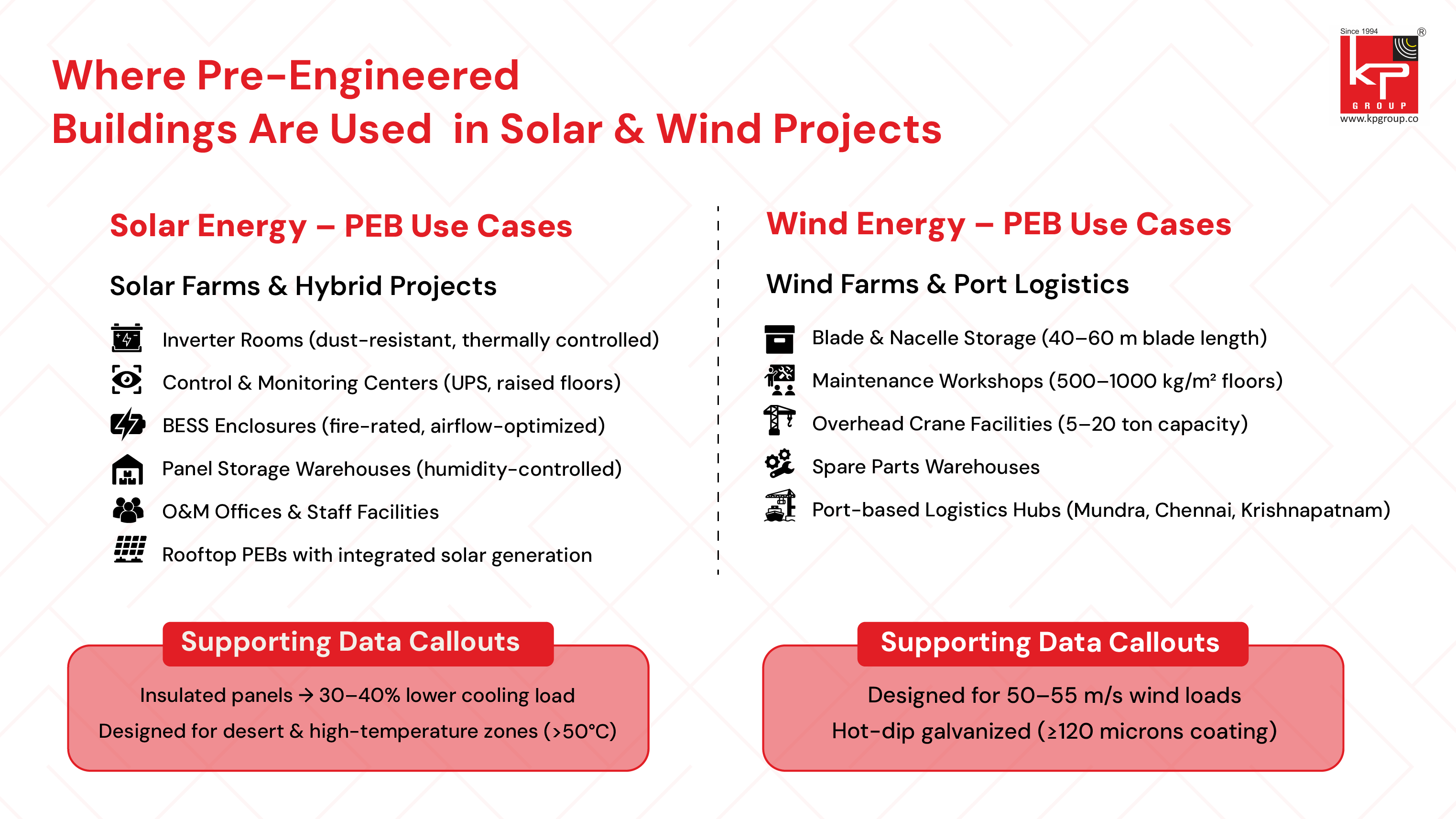

Pre-Engineered Metal Buildings for Solar Farms

Solar projects need various supporting infrastructure, and the use of PEB applications in solar & wind farm infrastructure has become common practice in the solar belt areas of India located in Rajasthan, Gujarat, Karnataka, and Andhra Pradesh:

- Inverter Rooms: Temperature-controlled spaces that house either string inverters or central inverters that change DC power to AC power. These buildings need to be thermally controlled, resistant to dust, and easily maintained. This type of efficiency is found in PEB design.

- Control and Monitoring Centers: Operations centers that generally have a raised floor to manage cables, roofs with added support for communication systems, and uninterrupted power supply (UPS) rooms that are able to oversee solar parks that spread over hundreds of hectares.

- Battery Energy Storage Systems (BESS): As solar-plus-storage projects are becoming commonplace, these structures are usually designed for a specific purpose as PEBs to provide fire rated enclosures, systems for airflow, and thermal management for lithium-ion or flow batteries.

- Staff Facilities and Administrative Blocks: Office spaces, canteens, and accommodations for the operations and maintenance teams that are working remotely at solar sites built with insulated panels to improve energy efficiency.

PEB structures are used in connection with solar rooftop systems. These buildings can serve a dual purpose as buildings that generate power while also storing equipment and using this design approach is becoming more common at solar projects for SECI and NTPC.

Pre-Engineered Structures for Wind Energy Facilities

Pre-engineered structures for wind energy facilities respond to a myriad of unique turbine maintenance and logistics challenges:

- Turbine Component Storage: Large clear-span warehouses to store large rotor blades, nacelles, and tower sections that are waiting to be put in place, or replaced while repowering.

- Maintenance Workshops: Heavy-duty structures with reinforced floors designed for servicing gearboxes, generators, and hydraulic systems and fitted with overhead cranes and specialized lifts.

- Logistics Hubs: Transit facilities at ports located at locations such as Mundra, Chennai or Krishnapatnam where turbine components are received, inspected, and prepped for transit to wind farm sites.

These structures also need to show resilience to high wind loads, and to resist coastal corrosion as hot-dip galvanized and/or marine-grade protective coatings.

Sustainability and Performance Advantages

The environmentally friendly aspects of PEBs align with the sustainability aims of using renewable energy:

- Reduced Embodied Carbon: The production of steel and PEB construction reduce embodied carbon by 40%-50% compared to equivalent concrete. Most structural steel has recycled content of 90%.

- Recyclable: Upon reaching its end-of-life, all PEB steel components can be 98% recycled without losing quality. This supports the goals of a circular economy.

- Energy-efficient Design: Insulated structural sandwich panels reduce cooling loads in inverter rooms and control centers, while translucent roof panels provide daylight harvesting and decrease artificial lighting needs during operational hours.

- Green Building Capabilities: PEB structures can easily achieve LEED (Leadership in Energy and Environmental Design) and GRIHA (Green Rating for Integrated Habitat Assessment) certification through sustainable material use, energy-efficient features, and water-saving measures.

Solar and wind developers increasingly recognize that sustainable building infrastructure is an integral part of their project ESG (Environmental, Social, and Governance) credentials and a developer's commitment to the needs and expectations of outside stakeholders and investor groups.

Use Cases and Real-World Applications

Solar Panel Storage Facilities

Applications: PEB in solar panel storage and wind turbine maintenance may extend to niche storage buildings for photovoltaic modules awaiting installation. These buildings need the following components are required:

- Temperature and Humidity Control: When maintained within optimal storage conditions, module degradation or hotspot issues can be avoided.

- Organization Racking Systems: Clear-span interior space will allow vertical storage racking systems that will allow more storage and allow for easier handling of materials during the previous phases of construction.

- Security Features: Perimeter fencing integration, controlled access points, and locations for CCTV mounts to secure high value inventory at remote project sites.

Solar parks which are leading the way that have been developed to date under the Jawaharlal Nehru National Solar Mission have already utilized standardized PEB designs to minimize procurement costs that are available through the ability to receive products via volume production and to establish benchmarks for subsequent projects.

Wind Turbine Maintenance and Equipment Warehouses

Wind energy's equipment complexity requires specialized maintenance facilities built around heavy, durable, Pre-engineered Building (PEB)* approaches:

- Overhead Crane Capacity: Facilities designed for the structural integrity of 5 to 15 ton overhead cranes to lift gearboxes, generators and other major components as part of periodic maintenance.

- Rapid Access Logistics: Roll doors and reinforced access ramps for mobile cranes and specialty transport vehicles to move equipment during emergency repairs.

- Workshop Areas: Dedicated mechanical repair, electrical testing, blade inspection, and spare parts storage areas all integrated into one PEB envelope that can be expanded as the fleet of wind turbines develops.

- Major wind power developers such as Suzlon, Vestas, and Siemens Gamesa have adopted a PEB style maintenance solution, for their Indian fleet installations, as they see the long-term operational benefits.

PEB, or pre-engineered building, is a construction that uses a steel frame with integrated solar power and modern construction methods. PEB simplifies the manufacture of the structure, but can also include significant ancillary solar power arrays.

Supply Chain, Installation, and Quality Control

The pre-engineered building supply chain and installation for renewables operates within a proven ecosystem:

- End-to-End Fabrication: From steel supply to galvanization, component fabrication, and quality assurance, all processes occur in controlled factory controlled environments certified meeting ISO 9001 and ISO 14001 standard.

- Galvanization and Corrosion Protection: Hot dip galvanized layer (80-120 microns minimum thickness) gives decades of corrosion protection, combined with powder or specialized paint systems for extreme environments.

- Logistics and Modularization: Components are packed for containerized freight and truck transport, with detailed sequencing to allow logical on-site assembly from foundations to roof.

- QA/QC Best Practices: Rehabilitation by Third party inspection agencies to confirm all dimensional tolerances, all welds, coating thickness on product, and torque values when necessary are confirmed following fabrication and erection, and meet Bureau of Indian Standards (BIS).

Experienced Pre-Engineered Building (PEB) construction company providers keep erection site manuals, train site supervisors, and provide warranty support for an extended period of time.

Future of PEB in India's Renewable Energy Growth

While India works quickly to achieve its renewable energy goals, the scope of PEB implementation will shift to new applications:

- Hybrid Solar-Wind Projects: A facility that integrates and co-locates control systems for two generation technologies, while affording PEB typology the benefit of accommodating various equipment arrangements.

- Green Hydrogen Production: Electrolyzer halls, hydrogen compression stations and associated storage for India's National Green Hydrogen Mission will heavily lever PEB, which permits fast deployment.

- EV Charging Models: Solar charging stations with battery swapping stations along highway corridors will utilize PEB canopies, creating shelter for cars while also offsetting power demand with renewable energy generation.

- Grid-Scale Battery Storage: Rapid evolution and demand for standalone BESS -battery energy storage systems- will continue as utility-scale projects assisting with grid stability/permitting fire rated and thermally managed PEB spaces meeting rigorous safety codes and regulations.

Build faster and smarter. Partner with KP Green Engineering for your PEB requirements.

Contact Us NowConclusion

Pre-engineered buildings for renewable energy sites are more than merely a construction solution, they represent a shift in how we think about infrastructure capable of supporting India's clean energy transition. The structural efficiency, climate-resistant qualities, and scalability flexibility associated with pre-engineered building systems embrace the interoperability and rapid construction pace necessary to meet renewable energy infrastructure delivery in support of national capacity targets. As intermediate products and energy storage, hybrid projects, or green hydrogen production are utilized, pre-engineered buildings are beneficial for their adaptability and proven performance across the developing renewable energy landscape.

Frequently Asked Questions:

Construction in remote sites can be fraught with challenges, particularly in terms of lack of skilled labor for conventional building. Conversely, PEBs can be deployed quickly with sites requiring a smaller crew. Sustainability: PEBs, like solar or wind, are composed of primary steel-based materials, and leaning into that connection makes sense when trying to link our new building projects to the clean energy mission in terms of storytelling and framing the projects for stakeholders and financiers.

About Us

KP Green Engineering Ltd. provides complete engineering and steel structure manufacturing solutions worldwide, serving industries such as renewable energy, telecommunications and beyond.

Get In Touch

Latest News

KP Green Engineering bags landmark order worth Rs 819 crore from BSNL for 4G telecom infrastructure

Gujarat Deputy CM Harsh Sanghavi Inaugurates KP Green Engineering's Matar Facility

KP Group and Kubota use IBM Maximo on Azure to streamline reporting, optimize operations, reduce costs, and support sustainability.