High Mast Lighting Poles: Design Considerations for Coastal and Industrial Use

Lighting systems using high mast poles have become indispensable infrastructure assets for illuminating broad outdoor areas. The high-mast lighting system is defined as a mounting height of 20m - 50m, and it produces a large functional light source in significant outdoor areas, unlike any other street or arena product. From bustling industrial sites to open coastal ports, high-masting pole systems continue to be a vital piece of infrastructure that delivers safety, operational efficacy, and visibility for nighttime use.

Importance of High Mast Lighting in Large-Scale Applications

High mast lighting offers strategic advantages that extend beyond the primary objective of providing illumination. In expansive environments, high mast lighting fixtures offer a more even distribution of light throughout a large zone by diminishing dark areas and shadowing that may create safety or security concerns.

High mast poles designed for industrial applications greatly reduce the total number of light fixtures needed to deliver an adequate amount of total light and lower the total installation costs, while also making it easier to maintain.

Overview of Coastal and Industrial Use Cases

Lighting of the high mast variety in coastal regions represents unique opportunities and challenges. Ports, shipyards, offshore oil platforms, and coastal roadways require reliable high mast lighting to endure harsh marine environments and to remain within the operating envelope.

Industrial areas of all types, including refineries, mining operations, manufacturing facilities, and logistics, need reliable and durable structures with suitable high mast lighting that operates 24 hours in demanding conditions. Both of these circumstances require dedicated design solutions that address the environmental loads, structural loads, and long-term performance of the installations.

High Mast Lighting Pole Design Essentials

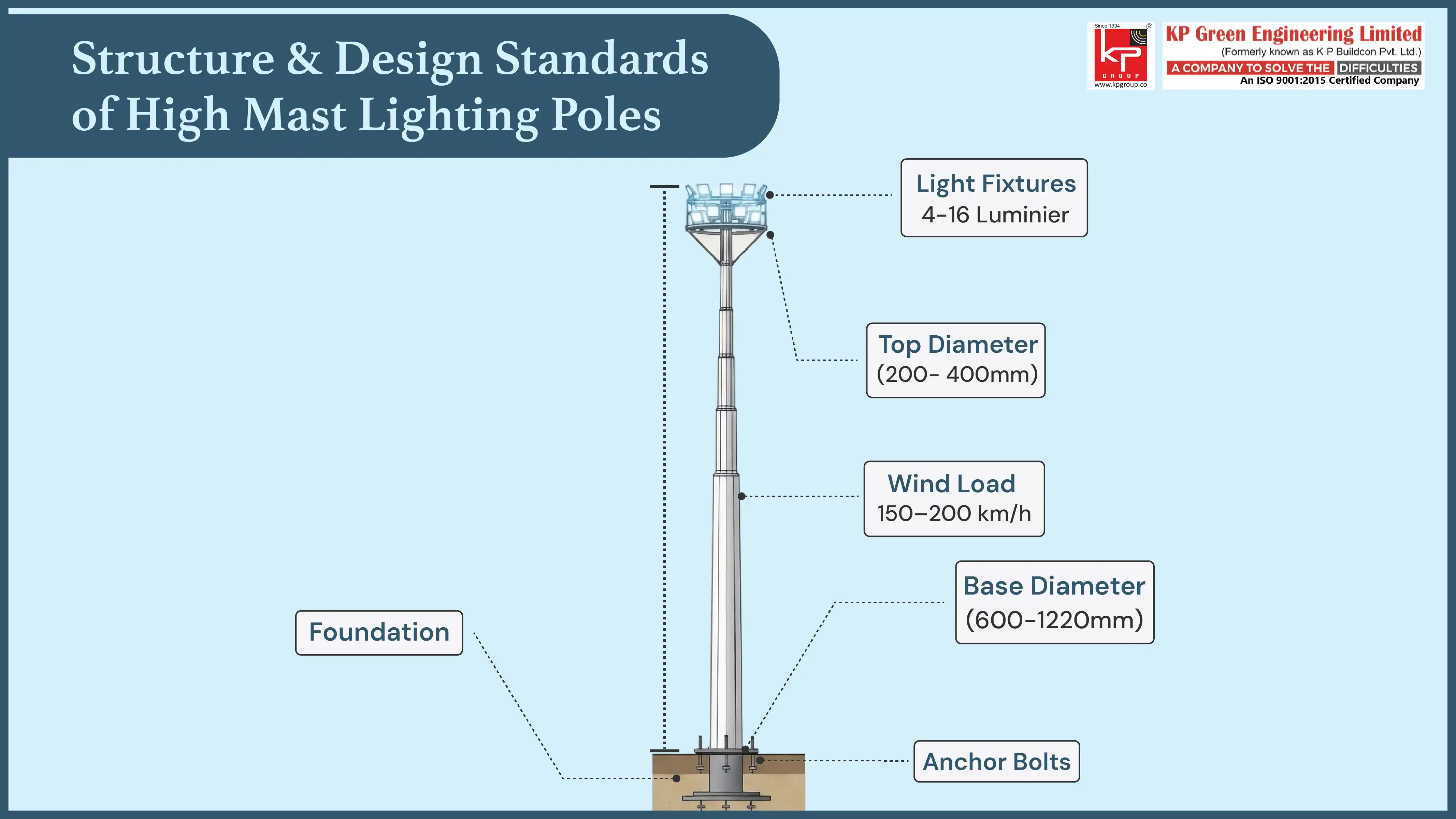

Key Design Standards for High Mast Poles

Design standards for high mast poles are formulated by numerous entities at both the international and national levels to promote structural integrity and safety in a bridge structure. The American Association of State Highway and Transportation Officials (AASHTO) outlines specific guidance for structural supports, while the International Electrotechnical Commission (IEC) provides resources for electrical components.

Standards provide constraints on wind load calculations, foundation criteria, fatigue resistance, and serviceability. In addition to following the established standards, engineers will need to consider site-specific factors such as geographic location, exposure category, terrain roughness, and if available, local wind speed data when designing to meet the codes.

Structural Requirements and Safety Factors

Structural analysis underpins the design process of reliable high mast lighting poles. Structural engineers must consider total load combinations due to dead loads, wind loads, ice loads, seismic loads and dynamic loads. Safety factors can be in the range of 1.5 to 2.5, depending on the application and local code requirements. The pole shaft must be designed to resist the maximum moment at the base and be controlled for the maximum deflection at the top of the pole. Connection details will be very critical, especially at the pole and foundation interface and at the luminaire mounting points. These details must be designed to prevent stress concentrations that will lead to fatigue cracks over time.

Material Selection and Galvanized High Mast Lighting Structures

The choice of material is a direct consideration for the useful life and performance of high mast installations. Steel is still the material of choice because of its performance characteristics, such as strength-to-weight ratio, ductility of the material, and relative cost.

Galvanized high mast lighting structures have become the accepted standard in the industry with the added benefit of superior corrosion protection through hot-dip galvanization. The hot-dip galvanization process forms a zinc coating that is metallurgically bonded to the steel, and it provides barrier-type and sacrificial protection from corrosion. Duplex systems are an option for closed applications in more aggressive environments, which combine the galvanized application with powder coating to ideally provide higher degree of protection.

High Mast Lighting for Coastal Areas

Challenges of Coastal Environments (Humidity, Salinity, Wind Loads)

Coastal infrastructure experiences a collision of environmental stressors that accelerate material degradation. The seawater-laden air created extremely aggressive corrosive conditions, where chloride ions can penetrate protective coatings and initiate pitting corrosion. High levels of humidity will maintain moisture on the wet-facing side of structural metal surfaces allowing an unbroken electrochemical process of corrosion to occur. Wind loads in coastal installations often exceed inland values due to decreased terrain roughness and exposure to tropical cyclones or hurricanes. Depending on the design wind speeds, wind speeds can be upwards of 200 km/h or more in cyclone prone areas. This requires designing for robust structural designs and reliable foundation systems.

Maintenance Practices for Coastal High Mast Lighting Poles

Maintaining high mast lighting poles in coastal areas calls for proactive methods. Washing poles with fresh water after a certain period can remove salt deposits before they build up and penetrate the protective coatings. Inspections twice each year for inspection of the integrity of coatings, the initiation of corrosion, or distress to structural components, can identify these forms of deterioration early in development. Coatings repaired using zinc-rich primers and compatible topcoats protect damaged locations. Electrical component inspection is especially important because salt creep along conductors can lead to short circuits or ground faults. Luminaire seals and gaskets also need to be replaced periodically to maintain ingress protection ratings. Different types of inspection and maintenance actions should be documented in order to have a historic record that will be useful over time when predicting service needs in the future.

High Mast Poles for Industrial Applications

Lighting Requirements in Industrial Zones

Industrial facilities have specific operational requirements for their lighting. Areas for manufacturing are required to have specific minimum levels of illuminance as prescribed by occupational safety standards, such as 200-500 lux for higher accuracy levels, depending on the precision of the work being performed. Storage and laydown yards are also required to have sufficient light to work equipment and to locate materials and equipment, for a typical range of 50-150 lux. Loading docks and material handling areas benefit from higher levels to mitigate accidents. The color rendering index (CRI) can also be important for quality control and visual acuity. New LED luminaires can be mounted on high mast steel poles that can meet all of these requirements in a very efficient manner while being much more energy-efficient with extended service intervals when compared to high-intensity discharge or HID lamps.

Durability of High Mast Lighting Poles Under Heavy Use

The durability of high mast lighting poles in industrial settings depends on design robustness and quality of construction. Vibration from nearby machinery, thermal cycling from industrial processes, and potential impact from mobile equipment create demanding service conditions. Fatigue-resistant details at welded connections prevent crack initiation under cyclic loading. Properly designed foundations distribute loads to stable soil strata, preventing settlement or tilting. Corrosion protection systems must withstand industrial atmospheres containing sulfur compounds, particulates, and other contaminants that accelerate deterioration. Quality fabrication practices, including proper welding procedures, surface preparation, and coating application, establish the foundation for decades of reliable service.

Safety and Compliance in Industrial Installations

Industrial high mast installations must comply with a variety of codes and standards. Electrical codes address wiring methods, grounding systems, and protection of circuits. Structural codes confirm the strength and stability of structures. Occupational safety regulations address protection of workers engaged in installation and maintenance. In hazardous classified areas, explosion-proof equipment and special grounding provisions may be required. Emergency lighting provisions make sure that a sufficient amount of illumination during loss of power will be provided. Certification documentation, based on structural analysis and electrical drawings and material, indicates compliance with codes to permitting authorities and insurance underwriters.

Maintenance and Longevity of High Mast Lighting Poles

Routine Inspection and Servicing Needs

Systemic inspection programs appear to be the foundation of high mast lighting pole maintenance programs. Annual inspections are visual inspections that identify noticeable defects, including coating damage, corrosion products or patterning, structural deformation, or loose wires. Detailed inspections occur every three to five years and will include non-destructive testing techniques including ultrasonic thickness measurements of the pole, magnetic particle inspection of welds, and dye penetrant inspections of critical details. Complete electrical system checks verify the proper function of the lowering devices, circuit function, and lamp function.

Preventing Structural Degradation Over Time

In order for the materials to stay safe and perform effectively over the long-term, mechanisms of deterioration must be curtailed before they become a threat to safety and performance. Protective coatings serve as an ongoing means of safety by limiting the progress of corrosion since loss of section will result in loss of strength. Areas that have potential for fatigue will receive additional attention, and this is especially true for any geometric discontinuities as stress will be concentrated in those areas. Drainage systems will be located to avoid accumulation of water that may otherwise lead to internal corrosion. Loose fasteners will be retorqued to specification to mitigate fretting corrosion and maintain connection strength. In cases where there has been deterioration, reinstatement techniques could include epoxy injection of cracks or helical piers used to fix settlement and restore foundation stability. Condition assessment data gathered at properties can lead to other proactive measures to address the developing condition before it manifests as a minor defect requiring full rehabilitation.

Conclusion

The successful implementation of high mast lighting poles design for coastal and industrial applications demands comprehensive understanding of environmental challenges, structural requirements, and maintenance strategies. Whether illuminating container terminals buffeted by salt spray or manufacturing facilities supporting continuous operations, these towering structures must deliver decades of reliable service under demanding conditions. Material selection favoring galvanized high mast lighting structures, adherence to established design standards for high mast poles, and commitment to proactive maintenance programs ensure these vital infrastructure assets fulfill their intended purpose throughout their economic life. As technology advances and operational requirements evolve, the fundamental principles of robust design, corrosion-resistant materials, and systematic maintenance remain unchanged, providing the foundation for safe, efficient, and economical illumination of our largest and most challenging outdoor environments.

Frequently Asked Questions:

About Us

KP Green Engineering Ltd. provides complete engineering and steel structure manufacturing solutions worldwide, serving industries such as renewable energy, telecommunications and beyond.

Get In Touch

Latest News

KP Green Engineering Scales Durable, Low-Carbon Infrastructure

KP Green Engineering bags landmark order worth Rs 819 crore from BSNL for 4G telecom infrastructure

Gujarat Deputy CM Harsh Sanghavi Inaugurates KP Green Engineering's Matar Facility