Crash Barrier Installation and Maintenance Guide

The reliability, quality, and durability of metal crash barriers are non-negotiable when it comes to safeguarding individuals on roads. As guardians of road safety, selecting the right crash barrier is paramount for ensuring the safety, integrity, and effectiveness of road infrastructure today. In this quest for excellence, KP Green Engineering emerges as a pioneer of innovation and a seasoned expert.

Also known as guardrails or metal beam crash barriers, they are essential safety barriers for road safety, reducing the severity of accidents for motorists and pedestrians. These robust, weather-resistant barriers are not just metal structures lining the roads- they are life-saving structures that aim to minimize fatalities and serious injuries in high-speed accidents and on highways.

Like any other skilled work, installation of a good, galvanized crash barrier is a specialized task that requires specialized engineers adhering to strict safety standards, as even the strongest crash barriers can fail if not installed in the right way. These crash barriers are designed and installed to absorb impact energy and redirect vehicles back onto the road in order to reduce the severity of accidents.

In India, there were over 1,317 accidents and 474 fatalities, translating to 55 crashes and 20 deaths per hour, according to The Indian Express. Now more than ever before, we need to focus on installing road safety barriers to reduce the number of road traffic accidents. Currently, there are various types of crash barriers, each having its unique characteristics and process of installation process. The type of crash barrier to be installed depends on different factors such as the type of road, the volume of traffic, specific requirements for the site, and pedestrian safety.

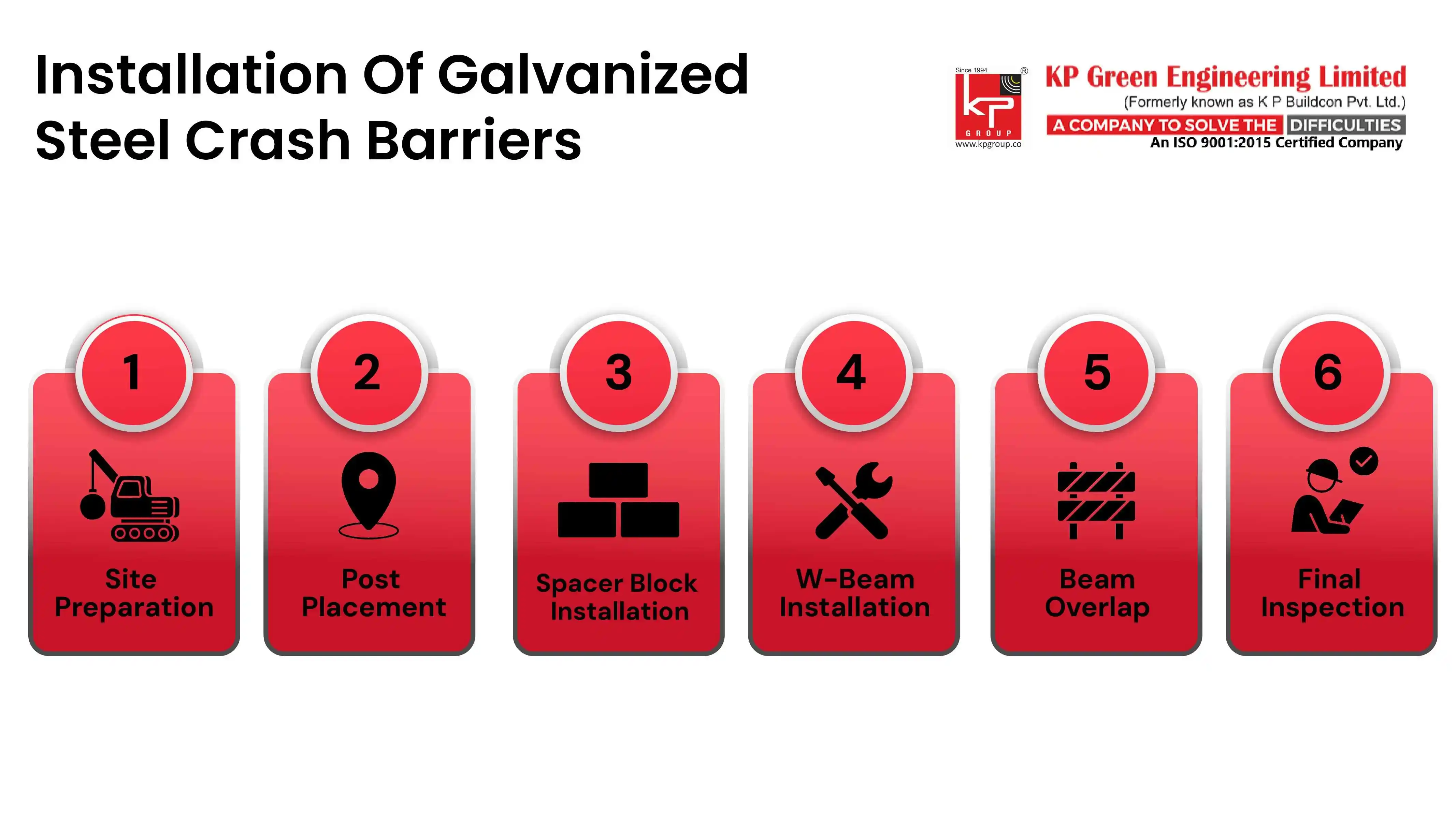

Installation Of Galvanized Steel Crash Barriers

To install galvanized steel crash barriers, it's crucial to begin with:-

1. Site Preparation

Assess and mark the designated installation area.

Ensure proper soil compaction for stable post anchoring.

2. Post Placement

Firmly install posts into the ground.

Maintain even spacing between posts (2–3 meters).

3. Spacer Block Installation

Fix small spacer blocks onto the posts.

4. W-Beam Installation

Align W-Beams carefully.

Bolt them securely to the spacer blocks.

5. Beam Overlap

Overlap beams at joints to ensure strength and connectivity.

6. Final Inspection

Double-check beam alignment (straight and level).

Tighten all bolts properly.

Ensure the barrier is solid, secure, and corrosion-resistant.

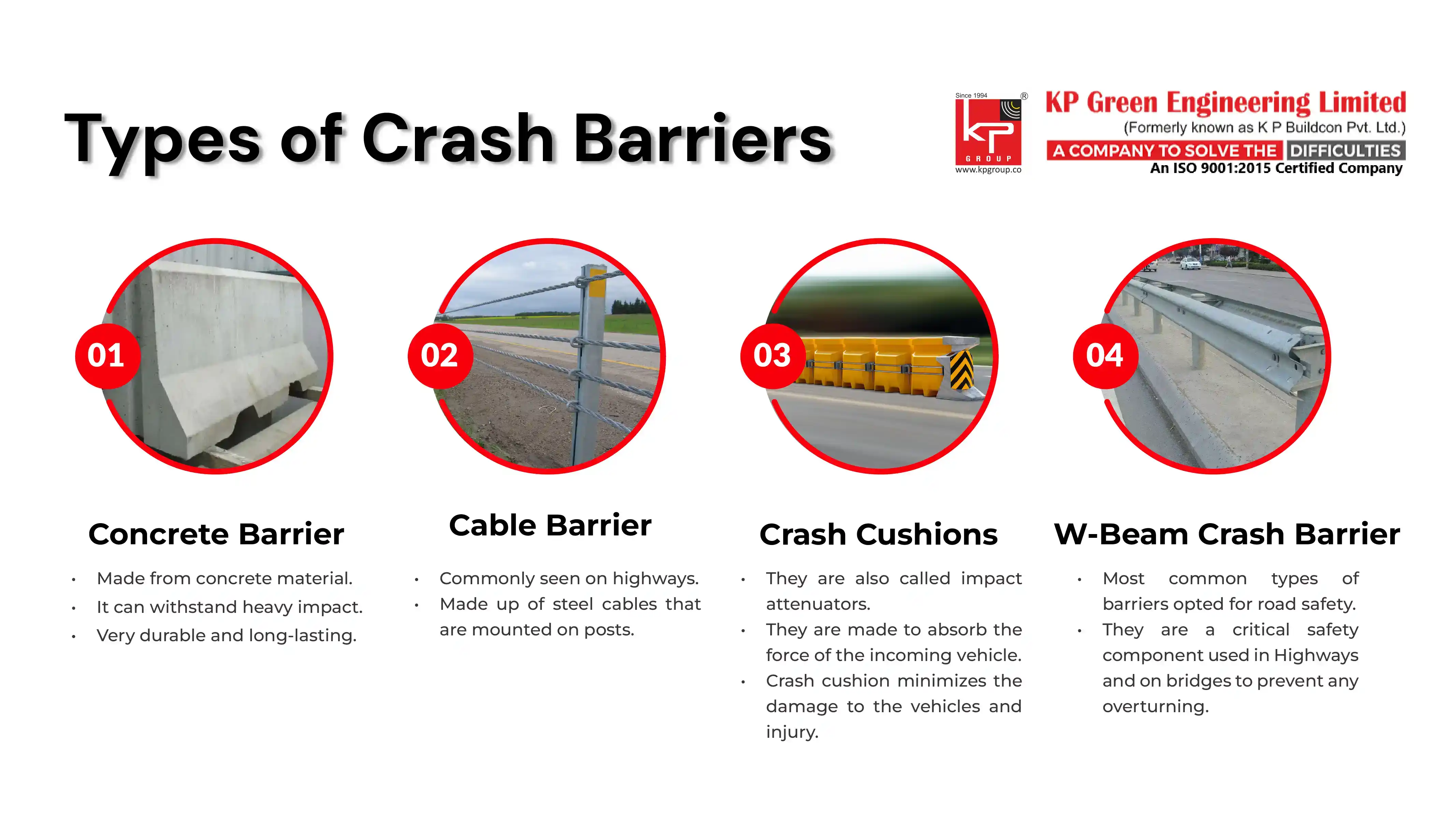

Types of Crash Barriers

Concrete Barrier: As the name suggests, concrete barriers are made from concrete material to withstand heavy impact on them, without the need to deflect the incoming vehicle. Concrete barriers are often put in areas where they want to avoid vehicle crossover from one lane to the other or a slide off the road. These barriers are very durable and long-lasting, even during peak weather conditions. Concrete barriers are also known to protect pedestrians on the road.

Cable Barrier: Cable barriers or wire rope barriers are commonly seen on highways today. They are made up of steel cables that are mounted on posts and constructed to catch and redirect vehicles, thereby preventing them from head-on collisions or leaving the road.

Crash Cushions: Crash Barriers, as the name suggests, are also called impact attenuators, are made to absorb the force of the incoming vehicle, reducing the severity of the accident. Due to their absorption ability, crash cushion minimizes the damage to the vehicles and injury to the passengers in the vehicle.

W-Beam crash barrier: One of the most common types of barriers opted for road safety on Indian roads in today’s time. They are a critical safety component used in Highways and on bridges to prevent any overturning. Keeping the objective of safety in mind, these barriers have become an inseparable part of road infrastructure today.

W-Beam Crash Barrier Installation Process

Installation of the W-Beam crash barrier requires one to have specialized knowledge and experience, to ensure that all the safety standards are met. The highway crash barrier installation process essentially involves:

Site Inspection: The first and foremost step involves cleaning the area, ensuring the soil conditions are right, leveling the ground, and marking the installation areas

Installation of the posts: Installing the metal posts on the roads at regular intervals and ensuring they are secured to the ground. It is recommended to have a space of typically 2-3 meters between each post.

W-Beam Attachment: The step involves one to connect and attaching the W-Beam to the posts using nut bolts and clamps. Ensure the nutbolts are secured tightly to avoid any loose connections and mishaps.

Inspection and final markings: This step involves an individual checking the markings, ensuring full support is provided at the end of the barrier, and checking for any loose ends that can cause harm in the future.

Crash Barrier Maintenance Guidelines

Though KP Green Engineering crash barriers require minimal upkeep, regular checks are vital for ensuring safety and preventing any major damage. Maintenance includes:

Checking for damage after any type of accident.

Inspecting for rust or any corrosion and re-painting the barriers.

Ensuring all the nut bolts are secured tightly to maintain integrity and safety at all times.

KP Green Engineering is taking a forward-thinking approach to public protection, making safety accessible to everyone. At KP Green Engineering, we believe proactive safety should never be something that is out of reach for individuals. Our expert team can help you choose and install a complete system of the best-suited crash barrier to reduce the risk of crashes on-site.

As more and more options are made available for various types of crash barriers, it's imperative to understand the specific usage, advantages, and the unique offering that each barrier provides, and choose based on the level of protection required. Taking an informed decision about choosing the right type of crash barrier is crucial in reducing the severity of accidents and frequency of it.

Frequently Asked Questions:

About Us

KP Green Engineering Ltd. provides complete engineering and steel structure manufacturing solutions worldwide, serving industries such as renewable energy, telecommunications and beyond.

Get In Touch

Latest News

KP Green Engineering bags landmark order worth Rs 819 crore from BSNL for 4G telecom infrastructure

Gujarat Deputy CM Harsh Sanghavi Inaugurates KP Green Engineering's Matar Facility

KP Group and Kubota use IBM Maximo on Azure to streamline reporting, optimize operations, reduce costs, and support sustainability.